State-of-the-Art Infrastructure

Foundry

- Natural gas-fired 3 Melting Furnaces of capacity 6MT, 10MT, 12MT

- PLC-Operated Hot Top Casting Machine

- PLC Operated Billet End Cut machine with Lot Marking & Stacking.

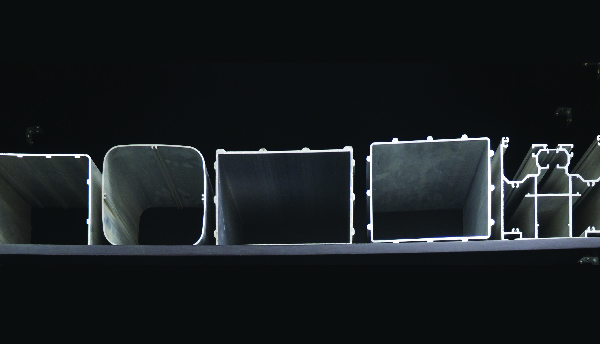

Extrusion

- 4 Fully Automatic PLC-Controlled Hydraulic Extrusion Line- 5,6,8 inches

- Fully Automatic handling system with 3-head Puller System

- Air, Water, Fog, Mist Quenching System PLC Operated

- Billet Cleaning Machine

- PLC-operated Ageing Ovens

- Automatic Packing Line

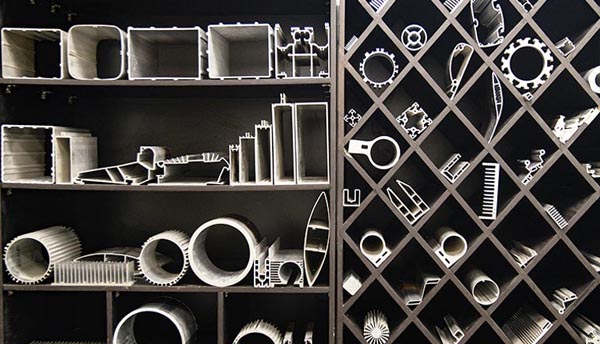

Extensive Die Library

We offer a diverse extrusion portfolio with over 6000 die designs accommodating profiles up to 300 mm.

- Q Form Stimulation Software

- Vacuum Die Nitrating Furnace

- In-house die development Facility having VMC, EDM and Wire cut, complemented by strategic partnerships with leading global die makers.

- Rockwell die hardness testing machine.

- Our expert design team delivers innovative, customer-centric solutions.

Energy & Environment

- 25% of our plant is running on Solar Energy

- Bag House Pollution Control System

- Water Treatment Plant

Quality Assurance

Our fully equipped laboratory includes:

- German Spectrometers for precise chemical analysis

- UTM for evaluating Tensile Strength and Elongation

- Portal Hardness Tester

- Automatic Die Polishing Machine for Surface Finish

- QA team ensures rigorous Quality Checks at every stage

New Initiatives

SAPL has recently entered the EV battery casing segment, expanding our innovation footprint in sustainable mobility solutions.